PZ-60 Tube Swaging Machine

-

Tube swaging machines come in various types, including manual, hydraulic, and pneumatic models. Manual swaging machines are operated by hand, while hydraulic and pneumatic machines use power sources to apply force. These machines typically consist of a frame, a swaging head or tooling, and controls to regulate the swaging process.

Swaging machines are used for a variety of applications, including joining tubes together, creating flared or tapered ends, reducing the diameter of tubes for better fitment, and forming complex shapes. They offer precision and consistency in tube forming, making them essential tools in manufacturing processes where tight tolerances are required.

- Phone:+86-15150208940

- E-mail:info@hlbender.com

Detail

Hydraulic tube swaging machine

Tube end swaging machine is our multi function production which uses abroad advanced high technology. It can be reduce and embossing in the pipes. This machine use set mold to process different caliber pipes when is reducing and embossing.

1.Applicable material of the machine: carbon steel, stainless steel, aluminum , alloy, copper, brass etc.

2. only for processing round pipe

| model | PZ-40 | PZ-60 |

| Max progress capacity | ¢40×2mm | ¢60×2mm |

| maximum working stroke | 450mm | 450mm |

| motor | 5.5kw | 7.5kw |

| driving method | speed reducer | Speed reducer |

| machine size(cm) | 1.1x1.2x1.5m | 1.9×1.2×1.5m |

| spindle rotation speed | 180r/min | 250r/min |

| machine weight | 1200kg | 1300kg |

PZ-60 Tube Swaging Machine

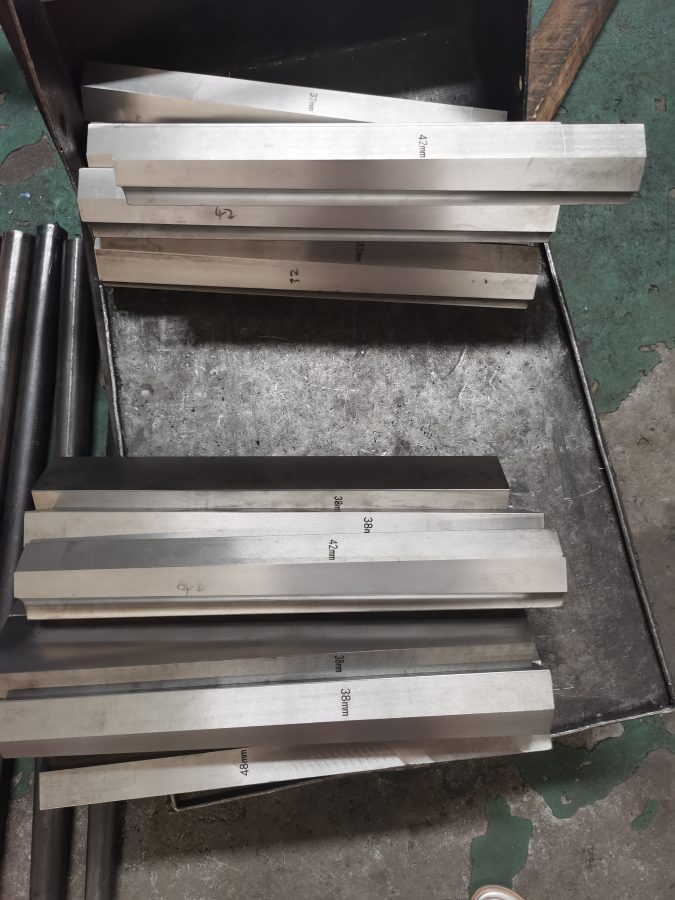

swaging mold

swaging mold

different tube OD for different swaging mold