CNC Pipe Bending Machine(SB-50CNC-3A-1S)

-

Direct supply from the manufacturer

- Whatsapp:+8615150208940

- E-mail:info@hlbender.com

Detail

A CNC tube bending machine is a specialized piece of equipment used to bend tubes or pipes with precision and accuracy. CNC stands for Computer Numerical Control, indicating that these machines are controlled by computer programs to execute bending operations.

CNC tube bending machines offer several advantages over manual or semi-automatic methods, including:

1.Precision: CNC control ensures consistent and accurate bends, even for complex geometries.

2.Efficiency: Automated operation reduces setup time and increases production throughput.

3.Versatility: These machines can handle a wide range of tube sizes and materials.

4.Cost-effectiveness: Despite the initial investment, CNC tube bending machines can result in long-term cost savings due to improved efficiency and reduced scrap.

They are commonly used in industries such as automotive, aerospace, furniture manufacturing, and construction, where bent tubes are required for various applications.

Automatic steel pipe bending machine SB-50CNC-3A-1S

Heli Automatic tube bending machines are widely used in a variety of areas of application such as automotive,motorcycle, aerospace, furniture, industrial vehicles, fitness equipment and other industries.The advantager of Heli cnc automatic steel pipe bending machine is that this machine can ensure the accuracy of bending pipe and achieve mass production at the same time, and help customers improve production efficiency.3D simulation program makes the operation easier. Heli cnc tube bending machine can bend all kinds of metal tube: steel pipe/stainless steel/copper/ aluminum tube .......round tubes/square tubes /rectangle tubes/oval tubes are workable for Heli cnc tube bending machine

1.2A1S means 2 servo motors and 1 stack tooling .

2.PLC+touch screen operating

3.Automatic feeding and rotation

4.can store 800 unit bending file.

5.can bend round pipe as well as square tube

6.can bend steel pipe, stainless steel pipe, copper pipe and aluminum pipe.

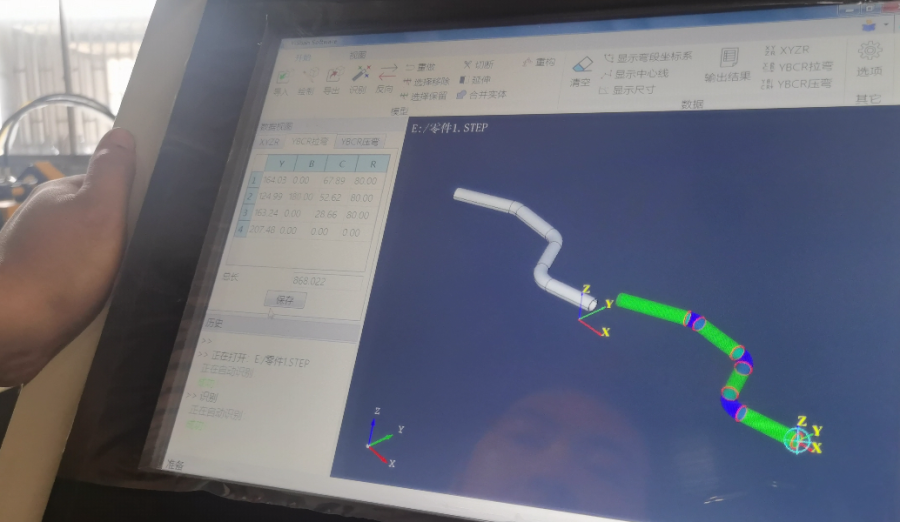

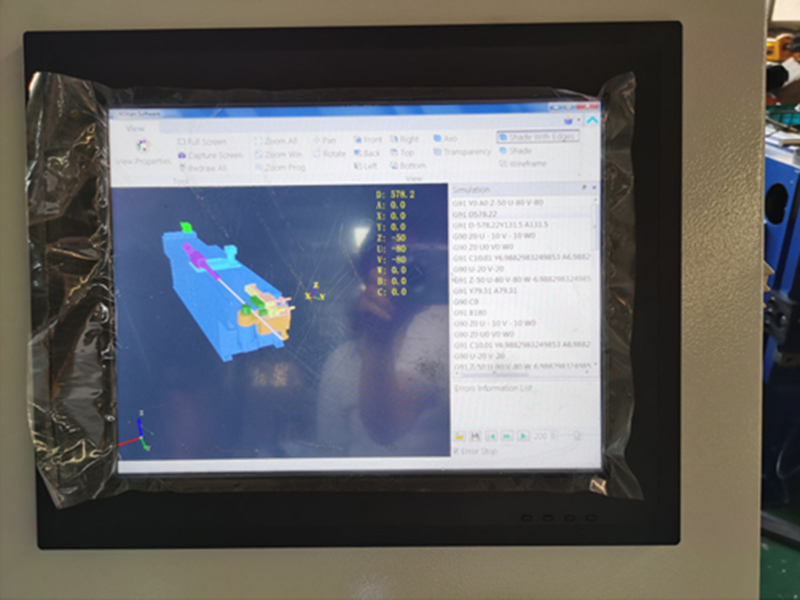

7.industrial computer with 3D simulation is available

8.Feeding-electric motor driven

9.Rotation-electric motor driven

10.Bending-electric motor driven

| machine name | cnc pipe bending machine |

| machine model | SB-50CNC-3A-1S |

| maxie bending radius | 250mm |

| maxi bending capacity | 50x2mm |

| range of bending angle | 0-180degree |

| plc | Omron |

| Electric servo | Mitsubishi |

| machine size | 4.4x0.9x1.35m |

| machine weight | 1800kg |

Bending drawing copy

3D simulation

workshop

workshop